For the reason that barrier material can improve the preservation effect and prolong the storage period of products, it has experienced a rapid development in recent years. Correspondingly, the wide application of barrier materials has also promoted the popularization of permeability testers. Since the conception of barrier material is rather new, a correct understanding of the barrier property as well as its correct testing is very important to actual production and selling.

1 Barrier Property of Materials

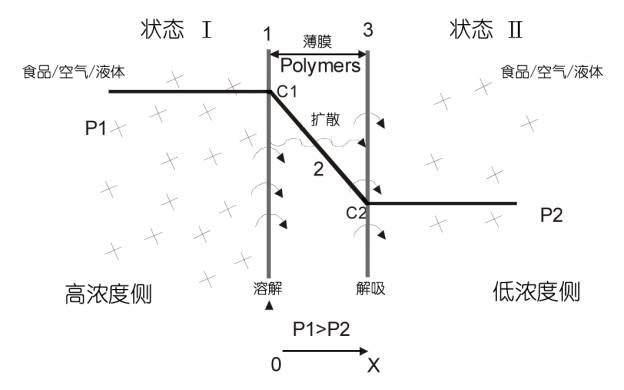

Barrier property is commonly in connection with particular permeable objects, which include common gases, water vapor, liquid and organic substance, etc. it refers to the property of material when specified permeable object transmits from one side to the other (from high density side into low density side). The whole transmitting process includes adsorption, dissolution, diffusion, and desorption. Gases or water vapor enter the surface of materials from higher density side. After diffusing inside material, it desorbs on the low-density side (see figure 1).

Figure 1. Transmitting Process

The speed of the permeation process depends on two factors. One is the speed of solution in polymer materials, i.e., solubility parameter. The other is the travel rate of permeable molecules inside the base of polymer, which is indicated by diffusion coefficient.

2 Classification and Interrelationship of Material Barrier Properties

Permeable processes of different objects through the same materials are different. According to the nature of permeable objects, barrier property of materials can be divided into barrier property of inorganic gases (i.e., the permeability we commonly say. It can be further divided into oxygen permeability, nitrogen permeability and carbon dioxide permeability, etc.), to water vapor barrier property (water vapor permeability), and to organic matter barrier property. Permeable principles of the three kinds of material are different. Moreover, owing to the difference of permeable objects, their permeable processes vary greatly.

Generally, when we say that barrier property of certain material is better, we refer to three aspects: better barrier property to inorganic gases, to water vapor and to organic matters. However, wrong ideas of generalization are common in describing barrier properties of materials. For example, materials with better gas barrier property is often considered as higher barrier materials, however, higher barrier material means that this kind of material should simultaneously possess better barrier property to gases, to water vapors and to organic matters. In fact, it is possible that this does not match with the reality in terms of its barrier property to water vapor and organic matter. EVOH has very high barrier property to gases in extremely low humidity, which will decrease significantly with the increasing of humidity. Moreover, its barrier property to water vapor is not good.

Special attention should be paid to the fact that even gas permeability (barrier property) to certain material varies in specific gases, such as oxygen and carbon dioxide. It has been proved by the test results that to one same material, there is certain proportional relation between its oxygen permeability, carbon dioxide permeability and nitrogen permeability. The reason is that permeable processes of inorganic gases are rather similar, with the dimension and shape of molecules as the main influenced factors. But, this proportional relation will change with different materials.

3 Avoid the Wrong Ideas of Barrier Property Testing

In choosing packing materials and corresponding structure designing, how to test barrier indexes of materials is the first problem to be solved. Test method and compatibility of test data are the focus of attention. Oxygen permeability test and water vapor permeability test enjoy rapid development because of great demand. The commonly used methods for oxygen permeability are differential-pressure method (vacuum method and normal pressure process) and equal pressure method (oxygen sensor method). Water vapor permeability can be tested with cup method and sensor method (humidity sensor method, infrared sensor method and electrolyzation method). All permeability testers are high precision instruments and their tests have strong environmental dependence, whose maintenance and operation cannot be compared by other common physical testing instruments.

One same permeability index can be tested with several methods. However, test data obtained from different methods do not have comparability. This is because different test methods result in different state of material during test process. For example, the most commonly used methods for oxygen permeability test are vacuum method and oxygen sensor method. But, test states of the material of those two methods are different. In vacuum method, two sides of the specimen have a pressure difference of 0.1Mpa, with one vacuum side and the other side with gas of 0.1Mpa. Under the pressure of 0.1Mpa, the microstructure of material will present some change. In oxygen sensor, there are gases of 0.1Mpa on both sides of the specimen with one side being oxygen and the other side being nitrogen carrier gas, only the partial pressure difference of oxygen is 0.1Mpa. Therefore, in principle, there is no comparability of the data obtained under different test method unless the correction factor is employed. Moreover, the demand for comparison of oxygen permeability testing should be executed under same ambient environment and with the same testing method.

4 Conclusions

With the popularization of the conception of barrier property, insiders of the packaging industry have the demand to further the understanding of barrier property. A further understanding of barrier property will not only help packing manufacturers design the structure of packing materials effectively and reasonably, but help the research personnel to better their performance of relating test as well.